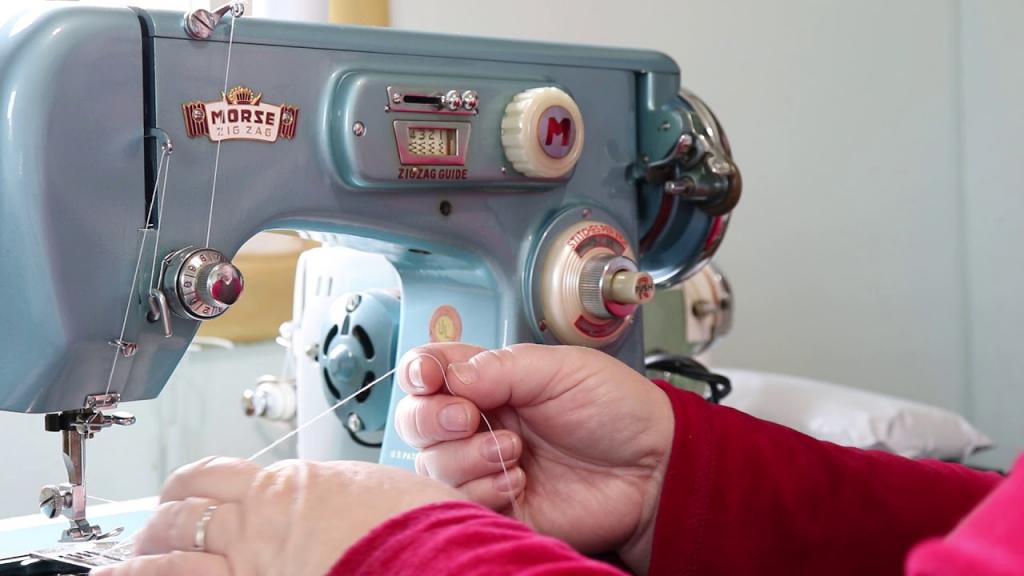

To make lovely handcrafted things, use an antique Morse sewing machine that is still in working order. The handbook may have been lost over time. However, you should not allow this deter you from using the device. Get the Morse sewing machine up and running and start producing something useful or fashionable.

How To Thread A Morse Sewing Machine Correctly

Step 1

Place the thread spool on the spool holder so that the thread is wound around the spool in a clockwise direction, toward the front of the machine.

Bạn đang xem: How To Thread A Morse Sewing Machine Correctly?

Step 2

Pull the thread to the first thread guide at the top of the machine’s back panel, then pull it back down. Straight across the machine to the front top of machine, pass the thread through the machine’s second guide.

Step 3

It is best to begin at the top and work your way down to the tension discs located at its center. After passing the threads through the tension discs, pull them around the discs to the right and then up to the left.

Step 4

Aim for the spool with one hand while simultaneously holding the thread end diagonally over the spool. Pull the thread straight up through the loop on the side of the tension discs with the other hand, bringing it closer to the tension discs at the front. Over the loop, down, and under the spring mechanism, the thread should be threaded.

Step 5

Using a needle and thread, slide the thread from right to left through the take-up lever’s hole.

Step 6

Second to last thread guide in front of machine, a few inches above needle: feed thread through this one. Then, take the thread and feed it through the loop that is directly above the needle.

Step 7

Begin at the front of the needle and work backwards. Finish by pulling the thread tail out to a length of about 6 inches.

How Do You Wind A Bobbin On A Morse Sewing Machine?

- To loosen the balancing wheel, turn the stop motion knob toward you.

- Place the thread spool on its pin, and thread the thread through the tension disc on the right side of the machine’s base, as shown.

- Seven times, wind the thread end around the empty bobbin.

- Assemble the winding apparatus, then place the bobbin on top and attach the spindle pin to the bobbin slot.

- The clasp must fit snugly against both the bobbin and the winder when the winder lever is pressed all the way down.

- Adjust the gimbal so that it points toward you.

- Turn off the bobbin when it’s completely full.

- Remove the bobbin from the spindle and cut the thread.

- To regain control of the needle bar, move the stop motion knob away from your body.

How to Date a Morse Sewing Machine

A Morse sewing machine can be dated using one of two methods. If you can discover documents going back almost 70 years, you can use their serial or model numbers. Another way to tell if a sewing machine is a good one is to look at the parts within.

Plastic was used to create a lot of different sewing machine parts. That trend started somewhere in the 70s and 80s. If your Morse sewing machine has plastic parts chances are that it is not more than 40 years old and that it is not a real Morse machine.

Many sewing machine parts were made from plastic. This fashion began in the 1970s or 1980s. Morse sewing machines that have plastic parts are likely to be less than 40 years old and hence not authentic.

He seemed to have rebounded from the court ruling about the infringement of the Trade Commission Act, but that rejuvenation only lasted for around ten years. At this time, no one knows for sure whether or not Morse sewing machines are still being manufactured, despite reports to the contrary.

How Thread A Bobbin Case On A Morse Sewing Machine?

- The thread tail should be 6 inches long when the bobbin casing is held up with the slot facing upwards.

- Thread the tension spring by threading the bobbin into its housing and pulling the thread through the slot.

- Take a thread and pull it toward the delivery eye to see if there’s any tension in it.

- It’s all about how much pressure you put on it

The Morse Super Dial sewing machine can use this guide. Follow the instructions in your Morse machine’s handbook exactly.

How Do You Date A Morse Sewing Machine?

Morse sewing machines can be difficult to date because the company itself went out of business many years ago, making it unable to acquire any documents. In order to find out the date of the manual, you will need to locate your machine’s serial number, search for it, visit forums, or talk to other Morse sewing machine owners. You can also use the Morse model comparison tool to get a sense of how old your device is.

Xem thêm : How To Fill A Bobbin On A Singer Sewing Machine Correctly?

Older Morse machines, for example, are made of metal and are estimated to be between 50 and 70 years old. Plastic machines, it is reported, are over 40 years old. Read our separate article about selling your old sewing machine if you’d want to know more.

Morse Zig Zag 550

As far as the specs go, it appears to be a good machine. However, the one we found was an unappealing shade of green, but the engine appeared to be functioning well.

The casing appears to be made of plastic, which helps to reduce the device’s weight. They weighed more than a ship’s anchor, but Morse sewing machines proved to be incredibly sturdy. In spite of its age, this one appears to be in fine functioning order with all its components.

When we tried to find the owner’s manual for this particular model, we were unable. The 4300 is talked about more than this model. There is a 1550 model out there, however it may not have the same skills and talents as the 550.

A 5500 model is also available, and here is a list of all the Morse sewing machine owner’s manuals that are still available.

Morse Zig Zag 4100

Some people have compared this model to the old cartoon figure Mighty Mouse, not only for its color selections but because it is a powerhouse of a sewing machine. Where people go wrong when this machine starts to fail is that they toss the baby out with the bathwater. This machine may be known by its more popular name the Fotomatic. There are a variety of these models still operating and it seems that they never lose their magical sewing powers no matter how many years have passed since their creation.

For more than just its color choices, this model has been likened to the cartoon character Mighty Mouse. One of the most common mistakes people do when this machine begins to malfunction is to remove the infant with the bathwater. If you’re familiar with the Fotomatic, you may recognize this machine as well. In spite of the fact that many of these models have been around for decades, it appears that they retain their magical sewing abilities.

In addition, the needle employs three different locations to complete your sewing.. Straight stitching is done on the left, while zig-zag stitching is done on the centre and right. As long as the needle plate and feed dogs are easy to find, you can still sew on a vintage machine without any issues.

Morse Zig Zag 4300

At the URL above, you may download the PDF version of the owner’s manual for roughly $10. Not to mention, this sewing machine offers everything you could ever desire in a sewing machine. Of course, given its age. Sewing machines all have one thing in common: they all have a needle. It doesn’t matter how old they are, if the needle is placed in the machine backward, they stop stitching. Many Morse 4300 sewing machines have the same problem. If you don’t put the needle in right, it won’t stitch.

When stitching, you don’t have to waste a single hand action because everything is simply accessible. In addition, disassembling and maintaining a sewing machine is not difficult. It only takes a few minutes to lubricate the machine, and after that, you should have no problems with it.

The good news is that the Morse 4300 is not that expensive to find. We saw one price at eBay for only $29 and others have said that the old machine goes for even less depending on where you find it. If you can fin done, don’t pass it by as the old Morse machines still work like they are supposed to.

Who Made Morse Sewing Machines?

The good news is that the Morse 4300 is not that expensive to find. We saw one price at eBay for only $29 and others have said that the old machine goes for even less depending on where you find it. If you can fin done, don’t pass it by as the old Morse machines still work like they are supposed to.

However, the Morse 4300 isn’t going to set you back a lot of money. On eBay, we spotted a price of just $29, but others have claimed that the ancient computer is considerably cheaper if you can find it. The old Morse machines still work as they should, so don’t waste your time if you can.

Pine and Toyota are two of the Japanese companies that have been cited as the actual manufacturers. There is no way to tell for sure who built Morse sewing machines because Morse hid the country of origin identification markings.

Rather, they exploited the Morse and Mercury brand names to deceive the American audience into believing that their equipment were manufactured in the United States. For decades, the corporation was in danger because of this.

Xem thêm : Sewing Basics: How Big Is 46 x 60 Blanket?

They have been found guilty of violating FTC regulations, but it’s not clear if any punishment has been done.

How Do You Thread An Old Fashioned Machine?

- Use the old sewing machine’s instruction manual as a guide

- The needle assembly should be raised after you’ve attached the thread to its end on the spool pin and done so.

- Thread the machine’s tensioner and spring using the guidance at the machine’s top.

- Reach another guide by guiding the thread underneath the take-up lever.

- Pull the thread through the needle by bringing it down towards it.

How Do You Use A Morse Zigzag Sewing Machine?

The Morse Fotomatic IV 4400 is an example of a zigzag sewing machine. Here’s how to sew with it according to the instructions in the manual:

- Raise the needle and re-enter the presser foot four inches of threads.

- Place the fabric underneath the presser foot after it has been raised.

- Press the foot down a little bit.

- It is necessary to turn to the right in order to get a needle closer to the material

- Stitch the material and begin sewing.

- Pulling on the fabric will only cause the needle to bend or break.

- Stop the balancing wheel after sewing to remove the fabric.

- Raise the presser foot and the needle

- Cut out the loose threads at the end.

How Do You Wind The Bobbin On A Vintage Sewing Machine?

- The old machine’s instruction manual is available online.

- Because vintage sewing machines lack automatic bobbin winding devices, you must wind the bobbin by hand.

- Remove the bobbin and get a thread spool from the machine.

- The thread should be tightly wound around the bobbin.

- A pen or other long, thin object can be passed through the bobbin and spun to help the thread wrap around it more quickly.

- It is time to put the bobbin back in its holder

- Remove a few strands of thread from the guide.

Conclusion

There you have it! A Morse sewing machine’s threading procedure is identical to that of other sewing machines. If you can’t locate your model’s manual, it’s preferable to speak with other owners rather than relying on the defunct Morse machine industry.

If you have any questions or suggestions, please feel free to leave a remark below.

FAQs

Who Made Morse Sewing Machines?

Morse only imported sewing machines that were based on machines from other manufacturers. You can find some similarities between the Morse sewing machines and those from Necchi, Sears Roebuck, and Nihon Mishin Selzo Kabushiki Kaisha if you look hard enough. Morse Sewing Machine and Supply Corp of New York City has long been assumed to have manufactured these top-of-the-line metal sewing machines. However, this is a far cry from the truth.

Pine and Toyota are two of the Japanese companies that have been cited as the actual manufacturers. There is no way to tell for sure who built Morse sewing machines because Morse hid the country of origin identification markings.

Rather, they exploited the Morse and Mercury brand names to deceive the American audience into believing that their equipment were manufactured in the United States. For decades, the corporation was in danger because of this.

Xem thêm : Sewing Basics: How Big Is 46 x 60 Blanket?

They have been found guilty of violating FTC regulations, but it’s not clear if any punishment has been done.

How Old is My Morse Sewing Machine?

If anyone has any idea what happened to the records, they aren’t willing to share. As far as we know, the manual for the Morse Fotomatic #17093 dates back to the early 1950s. So, if the serial number on your sewing machine matches that, it’s about 70 years old. When determining the age of a sewing machine, the serial number and old documents are the most common methods. Because the Morse sewing machine firm went out of business in the 1960s, this may be challenging.

Any current Morse machine that claims to be a genuine Morse is a fake because of the materials utilized in its construction. Newer models are plastic and only a few decades old.

If you’re using an all-metal Morse machine, expect to be in your 50s to 70s. In 1948, when the company was founded, there won’t be any older than that. Thus it may be impossible to date a vintage Morse sewing machine because of the lack of records kept in Japan.

Are Morse Sewing Machines Good?

The Morse sewing machines that were offered in the United States can’t all be the same, but on the whole, they’re a smart investment. This is the first time we’ve had a valid complaint regarding these devices.

However, despite the fact that their history isn’t the best, they were well-built and had parts that lasted for many decades. To boost sales, Morse may have tried to mislead the public about where the devices were created.

After all, the public’s anti-Japanese sentiments from the War lingered. In spite of this fact, it does not imply that these sewing machines were substandard. 60 years later, many are still working as well as they did when they were first installed.

The sewing machine’s long life is a testament to the craftsmanship and quality of the materials used in its construction.

Nguồn: https://spasifikmag.com

Danh mục: Sewing Tips