Sewing machines have a variety of timing options, however the hook timing is the most common cause of machine malfunction. The point at which the hook’s point of attachment meets the needle’s eye is referred to as the “hook timing” point. If you feel that your machine has timing problems, a close look at the needle and hook will reveal whether or not you’re right.

- What Size Needle For Sewing Fleece? A Perfect Guide For You!

- How To Measure And Sew Curtains? 8 Easy To Follow Steps For You!

- What Is A Free Arm Sewing Machine? Top Free-Arm Sewing Machine Models

- Where Can I Sell My Sewing Machine Near Me? 5 Tips to Remember

- How To Shorten Curtains Without Sewing? Complete Step-by-Step Guide

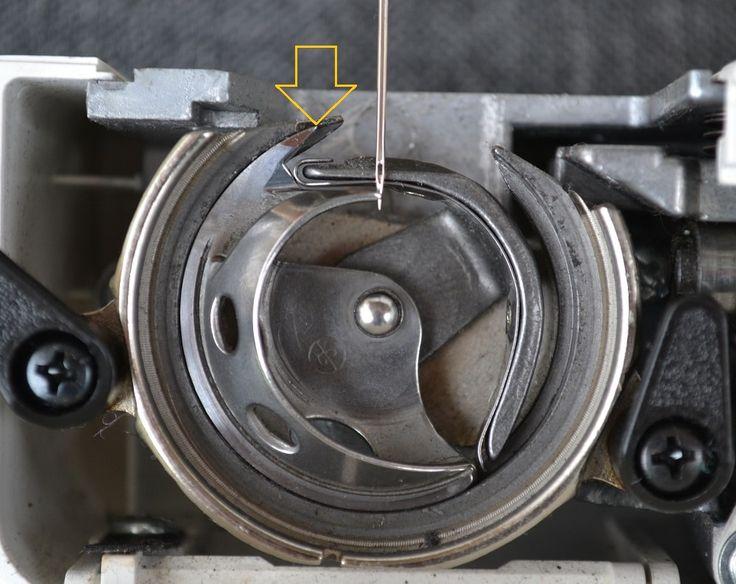

When the needle rises, it creates an opening between the needle’s eye and the substance in the back of the needle. This loop must be passed through by the hook’s tip to complete a stitch. This fundamental principle is followed by most sewing machines, regardless of the type or brand, however there is some fine-tuning that may be done.

Bạn đang xem: How To Fix Sewing Machine Timing? Ultimate Guide

Diagnosing and Fixing the Problem:

The first step is to confirm that you have the ability to adjust the timing. Verify the needle. Do they have a curved or a straight shape? The fabric you’re dealing with may necessitate a specific type of needle. Is it correctly and securely locked in place? Is the thread thick enough and suitable for the fabric? Thin needles and thread used for thicker cloth are the most prevalent mistakes.

On the other hand, an obvious clue points to the necessity of altering your timing. Inconsistencies in the length of your stitching are to blame. As a rule of thumb, this indicates that your computer’s internal components are out of sync. Remove the switch plate and slowly move the sewing machine with your handwheel to see if it works. This test can help you check that your thread is firmly attached to the material.

The sewing machine’s time must be adjusted if the hook isn’t working properly. However, while the specifics of the sewing machine’s instructions may vary, the overall concepts are quite consistent. If you want to be sure you’re doing it correctly, read the instructions. If you pay attention to how your sewing machine works as described in these instructions, you’ll be able to fine-tune the timer on your machine.

Xem thêm : How To Open A Pfaff Sewing Machine? A Few Tips to Remember

Sewing machines’ timing problems are almost always caused by the hooks. The needle is the most frequently encountered issue. The first place to look for a problem is at the machine’s timing.

-

- In order for the needle to move to the right, it must be moving clockwise.

- It must be dragged to the left if the hook is spinning counterclockwise

- The next step is to keep an eye on the hook’s point as it rotates. There are two ways the hook can get through this eye. The timing is considered “off” if it’s passing under the eye. It’s possible that the timing is off if the hook is positioned directly above the eyeball.

This is one of the most common concerns that sewing machine owners face. Set your machine’s settings to straight stitch if you know you’ll need to make changes. Simply remove its cover. Please do this if you haven’t previously. The following tools are also at your disposal:

- Screwdriver with a little flathead

- a flashlight or a lamp

- A ruler or a measuring tape.

- Oil for Sewing Machines

- Marker

How Do I Know If My Timing Is Off On My Sewing Machine?

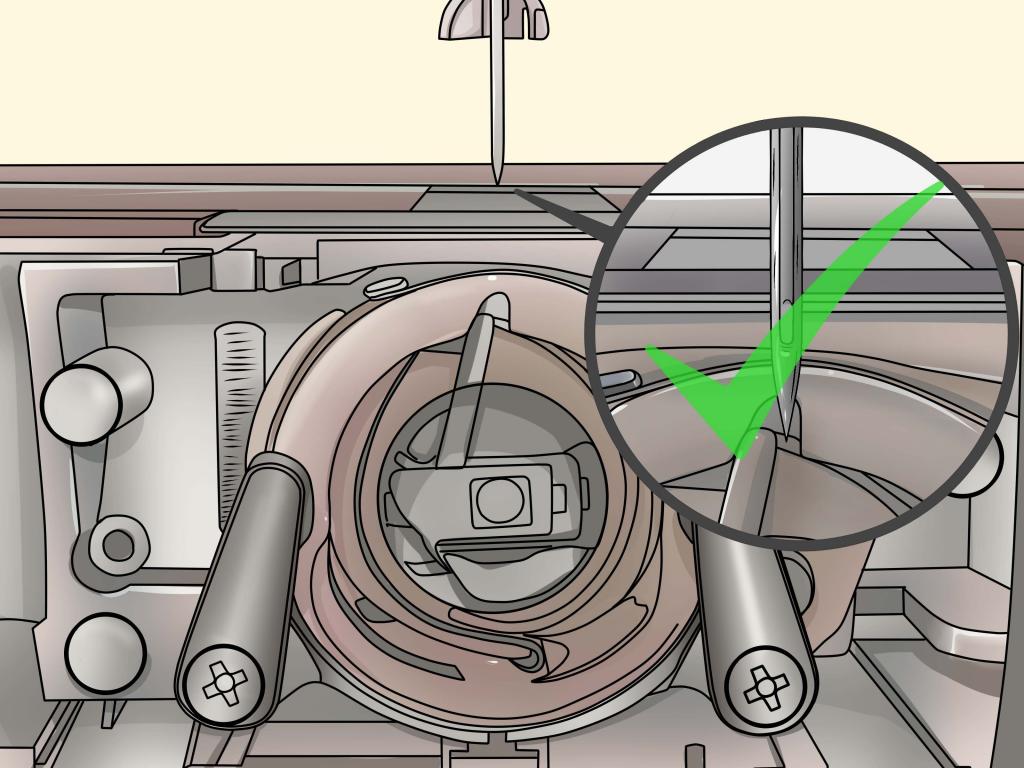

If your stitches aren’t uniform and your machine isn’t able to grab the bobbin thread, the timing on your machine may be incorrect. You can also run a timing check on your sewing machine to see if it’s out of sync. When you test this, make sure the needle hook and shuttle are aligned:

- Unscrew and remove the base cover, which includes switchplate and bobbin

- Check to see that the needle is threaded correctly and turn the handwheel.

- Take a look at the shuttle hook to see whether it’s getting the thread.

- It’s also possible to lower the needle to its lowest point and then raise it by 3/32 of an inch.

- Check sure the shuttle hook is higher than the needle eye.

How Much Does It Cost To Fix The Timing On A Sewing Machine?

When you hire pros to fix your system, you may end up shelling out more than $50. In the event that the techniques outlined didn’t work for you when you tried them out, this includes alterations to the timing. Any time you aren’t sure about a repair, you should have the device checked out by an expert. This will help prevent any further harm.

Simple Ways To Fix The Timing Of Your Sewing Machine

In this post, I’m going to share the way I’ve been using to get around this problem. You’ll be able to handle any problem that comes your way with this method. The best way to deal with a problem is to find the root cause of the problem, which is where the issue originates, and then eliminate or repair that source.

This principle states that the first step in fixing a problem is to identify what’s causing it in the first place. It is possible that the timing difficulties are caused by:

What Causes A Sewing Machine To Get Out Of Time?

Xem thêm : How To Remove Sewing Stitches? Complete Step-by-Step Guide

Incorrectly installed or misaligned components may cause the sewing machine to have timing issues. The accumulation of dust on your sewing machine can also cause complications. It’s a good idea to examine your computer once a year.

In some cases, a trip to the repair shop is not necessary. Instead, think about thoroughly inspecting the components and then putting them into place. It’s possible that a thorough cleaning and re-oiling procedure in line with your machine’s instruction manual could bring it back to life.

How To Adjust Sewing Machine Timing

If the needle is never trapped on the bobbin or hook case, you must alter the sewing machine’s timing. In addition, if the sewing machine is prone to missing stitches, there is a problem with the machine’s timing. You can fix the sewing machine’s time by doing the following steps:

- Replace your sewing machine’s needle with a new one.

- Remove the bobbin case needle plate and feed dog as well as the threads to make access easier.

- A straight stitch can be achieved by inserting your needle in the middle of the unit.

- Stop when the needle is about an inch above its lowest point by turning the handwheel.

- Make sure that your sewing machine’s hook is locked into place before attempting to rotate it.

- The needle’s eye should be located below the hook’s point.

- After establishing the needle’s time, adjust the feed rate.

Check out our guide on sewing machine maintenance if you’d want some advice on keeping your machine up and running. Maintaining a high level of performance on the equipment will assist in preventing degradation.

How Do I Know If My Timing Is Off On My Sewing Machine?

A problem with your sewing machine’s timing could be the cause of inconsistent stitches and a lack of thread from a bobbin. It’s also possible to do some tests on your machine to see if the timing is off. The shuttle and needle hooks should be aligned properly for this exercise:

- Remove the bobbin case, switchplate, and base cover.

- Check to see that the needle is threaded correctly and turn the handwheel.

- You should make sure that the shuttle hook can capture the thread without difficulty.

- The needle can be lowered to its lowest point and then raised by 3/32 inch as a different option as well.

- Check sure the shuttle hook is higher than the needle eye.

Conclusion

To avoid having to buy a new sewing machine or paying a repairman’s fees, you may fix the timing on your sewing machine yourself in a few simple steps. We recommend that you read your owner’s handbook and warranty before beginning, however there are numerous benefits to maintaining yourself and your sewing machine. As long as you follow these simple instructions and the owner’s guide, anyone may simply modify the tempo of their sewing machine!

Nguồn: https://spasifikmag.com

Danh mục: Sewing Tips