There are two basic steps for a beginner who wants to learn how to stitch nylon webbing using a sewing machine: Nylon webbing is used for heavy-duty applications because of its hardness, thus sewing it on a sewing machine is difficult.

In this post, you’ll learn how to sew nylon webbing and get sewing instructions. Be sure to check out the best heavy-duty sewing machines to ensure that the machine can handle nylon webbing without jamming or failing.

Bạn đang xem: How To Sew Nylon Webbing On A Sewing Machine? Complete Guide for Beginners

Are you meeting your company’s needs by utilizing nylon webbing? There are a number of excellent industrial sewing machines available, and we’ve examined a number of them.

Is Nylon Easy To Sew?

In addition to the materials already mentioned, you’ll also require two additional items in order to complete this task successfully. Having the correct tools is the first step to making any task easier. To begin with, you’ll need to be patient. A lack of self-discipline can be a problem for certain people. It’s not a difficult task to complete. When you simply need to fix a small section of nylon web, hand sewing is a better option than using a sewing machine.

Sewing nylon webbing slows you down, which is beneficial in today’s fast-paced world. It’s a great way to wind down, take pleasure in the moment, and feel good about yourself. There is nothing more satisfying than finishing a project and spending some quality time with yourself when you learn how to sew nylon web.

Pushing that huge needle through the material may become unpleasant if you don’t wear a thimble on your finger. Pull the needle through the opposite end using a pair of pliers as well. You need a firm grip to get the needle to the other side of the fabric because needles can be slick.

How To Sew Nylon Webbing On A Sewing Machine For Beginners

Step 1. Preparation of the materials

- Using nylon webbing, measure the desired length.

- A ruler should be laid on the webbing, and a soldering iron should be used to crimp the nylon before cutting.

- Cut along the soldered lines with a sharp knife, being careful not to let the ruler slip.

- To prevent the new nylon webbing from fraying, hold a torch to it.

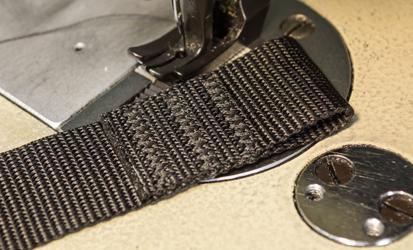

Step 2. Webbing made of nylon is sewn

- To make sure the nylon webbing is the correct size, the edges should be bent inward.

- Webbing made of nylon should be sewn onto your sewing material, not on top of it

- Use an X-stitch on both sides of your webbing to begin stitching a box.

- With the help of a double knot, sew the stitches into position.

- When the box is sealed, use a lighter to ensure that the stitches are strong.

Is the box stitch something you’re not sure about? The following are the measures to take:

- The nylon webbing should be sewn in a straight line from end to end.

- When you raise the foot of the machine, rotate the webbing 45 degrees. Take care not to yank out the needle.

- Create a one-inch-long straight line.

- The second step should be followed by the same procedure.

- A straight line of the same length as the one you traced in the previous step should be drawn in this stage.

- Step 3: Trace a diagonal line as long as the straight line you just drew, all the way to the edge of the third-step straight line.

- Sew in a straight line until you reach the two previously sewn corners.

- To draw a diagonal line over the previous diagonal line, go back to step two and repeat it.

- Step two is a repeat of step one. When you get to the last two corners, continue to draw a straight line.

- Make another diagonal line by repeating the second step.

- Step 2: Draw another straight line over your first one by repeating Step 1.

- Turn the nylon webbing 90 degrees by lifting the foot of your sewing machine. However, do not remove the needle from the syringe at this time.

- A straight line should be drawn over the one you traced in step 11

- Over the line that you drew in step 5, repeat step 14 and draw straight lines across it.

- When you’re done with step 14, draw a straight, even, and continuous line across the line you made in step 9.

- Backstitch two times at the end of the box stitch with X to finish.

- Get rid of any extra threads.

Can You Sew Nylon Webbing With A Regular Sewing Machine?

Using a sewing machine to stitch nylon webbing is not suggested because the material is exceedingly robust. You may find that stitches are missing or that your machine is unable to function.

A better option would be to get a high-end sewing machine or an industrial machine capable of sewing materials like nylon, which are robust and hefty. You’ll be able to stitch more fast and precisely with this method.

If you observe that the machine is frequently jamming, you should investigate further.

How to Sew Nylon Webbing By Hand (Size Needle and Thread)

Sewing by hand isn’t outdated because of the availability of sewing machines. Hand stitching can be the best option in some cases because there is nothing to break down and you are less likely to lose your thread. In the event that the power goes out, hand stitching is an excellent option. You can pretend to be a pioneer in the 19th century.

Technology-phobes should avoid hand stitching. Nylon webbing and other sewing jobs can be easily handled with this tool. You only need a size 18 needle, nylon thread that has been pulled halfway through so that it is doubled, and you’re ready to start.

Continue reading this article to learn more about hand stitching nylon webbing. In order to save you time, it provides an in-depth look into the subject matter. Investing time in research is a waste of time that may be better spent stitching.

Can You Sew Nylon Strap?

A vintage or antique sewing machine is ideal for sewing nylon straps. Nylon is no match for these sewing machines, which are made to withstand the rigors of everyday use. Yes, you can accomplish this by hand, but you may not have the power in your hands or wrists to do so. A heavy-duty sewing machine is required to sew through the webbing and the several layers, so you may not have one at home.

A good industrial machine may be necessary if you can’t get one of those at a fair price. These machines are equipped with the necessary motor power to ensure that the needle and thread perform as intended.

Xem thêm : How To Line Curtains Without Sewing? Complete Step-by-Step Guide

You’re in luck if you have a Kenmore 158 series sewing machine. The straps or webbing are sewn together beautifully in this series, which tackles ylon.

What Thread To Sew Nylon Webbing

Alternately, you can use upholstery thread, which is tough enough to hold the webbing together even under the harshest conditions. Bonded nylon thread, such as #69, is also an excellent choice. There are a number of threads that you can experiment with. No matter what type of fabric you use, vinyl threads will not sew up nicely. When sewing nylon webbing, nylon thread is a popular choice, and it’s a good idea to use it.

It should be simple to track down materials of this nature. Make an appointment with your local fabric store or visit one of the many big-box hobby stores that are available around the country. Other big box retailers and Amazon are also good options for finding the thread you need.

Make sure you have enough thread because you’ll be doubling it up and using twice as much as typical. If you’re going to start stitching nylon webbing, you’ll need at least 2 feet of thread in the needle’s eye.

What Size Needle To Sew Nylon

Sewing nylon calls for a wide variety of needles. Depending on the nylon you’re working with, you’ll want to select the appropriate tool. Ripstop nylon, for example, just requires a 70/10.

In order to stitch nylon webbing that is thicker and stronger, you’ll need a needle size 18 and nothing smaller. If you’re sewing by hand or with a machine, this is the needle size you’ll need.

The thicker threads, such as the #69, are what you need to keep an eye out for. Bigger eyes are needed to see through nylon. If you use smaller needles, you run the risk of stripping the thread’s thickness and weakening it significantly.

When it comes to needles, you can’t skimp. If you want to go down to the smallest possible size, then choose for the size 18. It is possible to sew up to a size 20 or even a size 22 and be successful.

Can You Sew Ripstop Nylon?

One of the most important aspects of stitching nylon ripstop is not to pin the material. Instead, use painter’s tape. That manner, you preserve the fabric’s integrity. Maintain a straight stitch line as you sew. Nylon has a grid that can serve as a helpful guide to keep your design looking uniform. A 70/10 needle would be ideal for this job, and yes, it is a possible. However, you can get away with polyester or other sorts of nylon when it comes to the thread.

In terms of stitch length, you don’t want any little or slender stitches. You may want to go with a medium size, but make sure you have the correct length first. When stitching this cloth together, a topstitch can be used to strengthen your threads.

Finally, use razor-sharp scissors to cut the fabric, a good reminder to check your needles to ensure they are sharp, new, and unbent.

How Do You Sew Nylon Mesh Fabric?

There are a few things to take care of initially. When stitching mesh fabric together with a sewing machine, you need to use upholstery thread. To ensure that your mesh stays in place, choose a strong thread like this one.

The next step is to sew with a loop stitch, and then tie the threads together with an overhand knot after stitching all the way around. The key to working on a mesh is to move carefully; don’t let your machine race or speed up, because going too fast will definitely burn out the engine.

Also, be ready to sew around the mesh multiple times to ensure that it holds together effectively. The delicate nature of mesh calls for extra stitches to prevent the material from being overworked. Make sure that your tensions are set correctly.

How To Sew a Nylon Flag

The most critical step is to get started. First, you need to determine what you want on the flag. There are no limits to what you can do here. After that, you’ll need to create your pattern, which you may accomplish on a computer with a variety of applications.

The next step is to gather your materials and trim them to size according to the colors you require. After threading your sewing machine with a high-quality nylon thread, set the proper tensions. Obviously, different thread types can be used for different projects, depending on the type of nylon being used.

If you’re working with thicker nylon, go with a size 18+ needle and a 70/10 universal needle. Using a stitch length that is strong enough to withstand the wind and other weather conditions, begin sewing the flag’s components together.

Xem thêm : How To Sew A Blanket For Beginners? Step-by-Step Tutorial

In a matter of months, the paint will begin to fade.

How Do You Cut Nylon Fabric?

Nylon is best cut using razor-sharp scissors. As a last step, make that your cut is perfectly straight. Fraying is a concern while cutting nylon since nylon is prone to fraying.

Another method of cutting nylon is with a rotary cutter that is extremely sharp. The possibility of fraying is not eliminated by using this cutting instrument. To proceed with your sewing job, you must first address the problem of fraying.

It is possible to cut ripstop nylon using one or both of these methods, which is called hot cutting. With the use of a soldering iron, you may stop the fraying process in its tracks before it ever begins. Keep your furniture, carpet, and other belongings safe by using this procedure on a good piece of glass.

Can You Sew With Nylon Thread?

The thickness of the nylon you are sewing affects the type of thread you use. Thick nylon need a stronger thread. A larger needle is required when you switch to thicker thread. Yes, and this is one of the most commonly used threads for sewing nylon. The needle’s eye will need to be larger the thicker the nylon thread is. When sewing with nylon thread, you are increasing the project’s durability.

Polyester thread can be used instead of nylon thread to sew nylon, however nylon thread is preferable.

7 Tips for Sewing Ripstop Nylon Fabric

It’s surprising how frustrating it may be to sew thin fabrics like ripstop nylon for the first time compared to heavier ones. If you plan to sew using ripstop, you’ll need a needle and thread designed for heavy-duty materials. It’s also possible to use painter’s tape if you need to cut something. A micro denier is more difficult to deal with than a coated ripstop like our 70D water repellent ripstop nylon. If you’re still having trouble, here are a few more ideas to consider.

- Use a brand-new, razor-sharp Universal 70/10 Needle when sewing.

- A polyester or nylon thread that can be used for everything is ideal. Some people prefer to match the thread color to the cloth color, while others prefer to do the opposite. That is, if you’re using nylon cloth, use nylon thread that’s the same weight. It’s fine to use all-purpose thread as well.

- Slipping? If you’re using coated ripstop nylon, you shouldn’t have too much trouble with slipping while working. To avoid having to pin your seams through your ripstop, you may just use painters tape to hold them in place. As a final option, a long-running basting stitch on the edge can help prevent slippage!

- Sew straight. Sewing straight is made easier by using the ripstop’s grid lines. A crooked seam will be easily spotted if it contrasts with the fabric’s straight woven lines. It’s important to remember that ripstop tends to expand diagonally.

- Sharp scissors or a new rotary cutter are the best tools for achieving perfectly straight edges. Sewing your parts together as soon as they’ve been cut out is recommended. Making stitching more difficult if you leave cut nylon about can make your clean cut edges sloppy or frayed.

- Always double-check your stitching. If your stitch length is too little, it might weaken your seams by perforating a line down your cloth that can readily come apart over time. As a general rule of thumb, aim for about 8-10 stitches per inch.

- Reinforce the seams. If your creation will bear weight, use a topstitch to reinforce the seams (felded seam). It will strengthen your seams and make the finished product look more professional if done correctly.

FAQs

What needle should I use for nylon webbing?

Webbing is best sewn with a heavy-duty universal needle. A new needle should be installed in accordance with the instructions provided by your sewing machine. For heavier materials, use a 90/14 or 100/16 needle; for extra-heavy ones, try a 110/18 or 120/19 needle.

Can a regular sewing machine sew webbing?

When the tension is increased, my machine performs better with webbing. Don’t give up on your Brother just yet; I know my Janome machine can sew through multiple layers of webbing with no problem. A lot of standard home computers could do it. I recommend using Tex 45 nylon thread and a regular needle in that machine.

Can you sew nylon webbing?

Once you’ve decided on your webbing, you’ll need to figure out what kind of thread and needle size to use with it. When it comes to sewed loops, the best threads to use are Bonded Nylon and Polyester. They have a high tensile strength and are quite durable.

Is nylon hard to sew?

Ripstop nylon is impossible to stitch because of its unique qualities. So you can use it in a variety of applications and projects. When stitching with ripstop nylon, keep your needle in mind.

Does bonded nylon thread melt?

As time passes, the low melting point, “yellowing,” and brittleness of nylon threads make them unsuitable for use in sergers or invisible monofilament sewing machines.

Does Gorilla Glue work on nylon straps?

In order to attach nylon to another material, you may need to combine Loctite Super Glue and J-B Weld Plastic Bonder as well as Original Gorilla and Elmer’s Carpenter’s Glue and E6000.

Conclusion

It’s all done and dusted! As long as you have the right tools and settings, learning to sew nylon webbing on a sewing machine isn’t that difficult.

However, you must be able to produce the box X stitch. When it comes to practicing with nylon webbing scraps, you don’t have to worry about it.

It goes without saying that a machine capable of stitching nylon webbing must be employed.

Nguồn: https://spasifikmag.com

Danh mục: Sewing Tips