Missed stitches on your sewing machine are making your heart race, and you’re panicking.

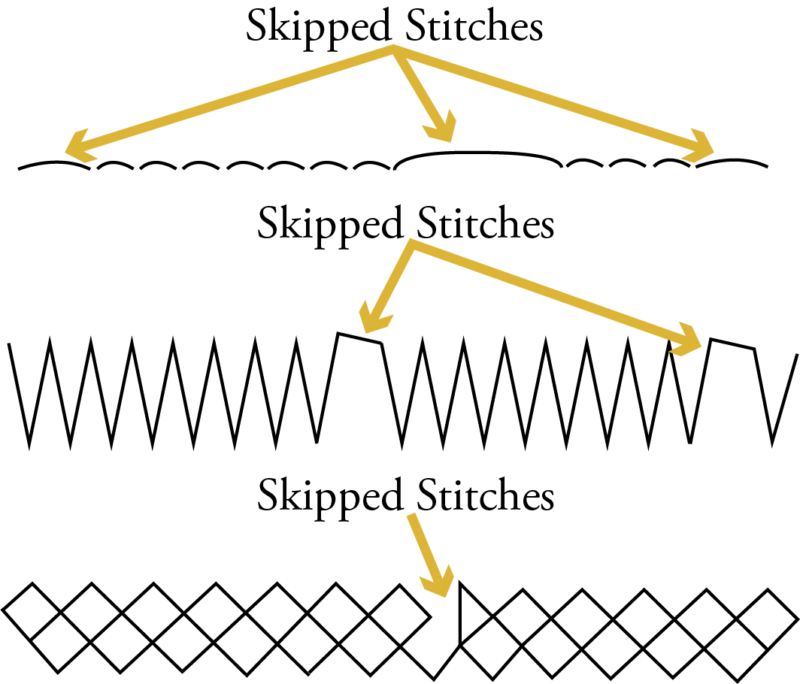

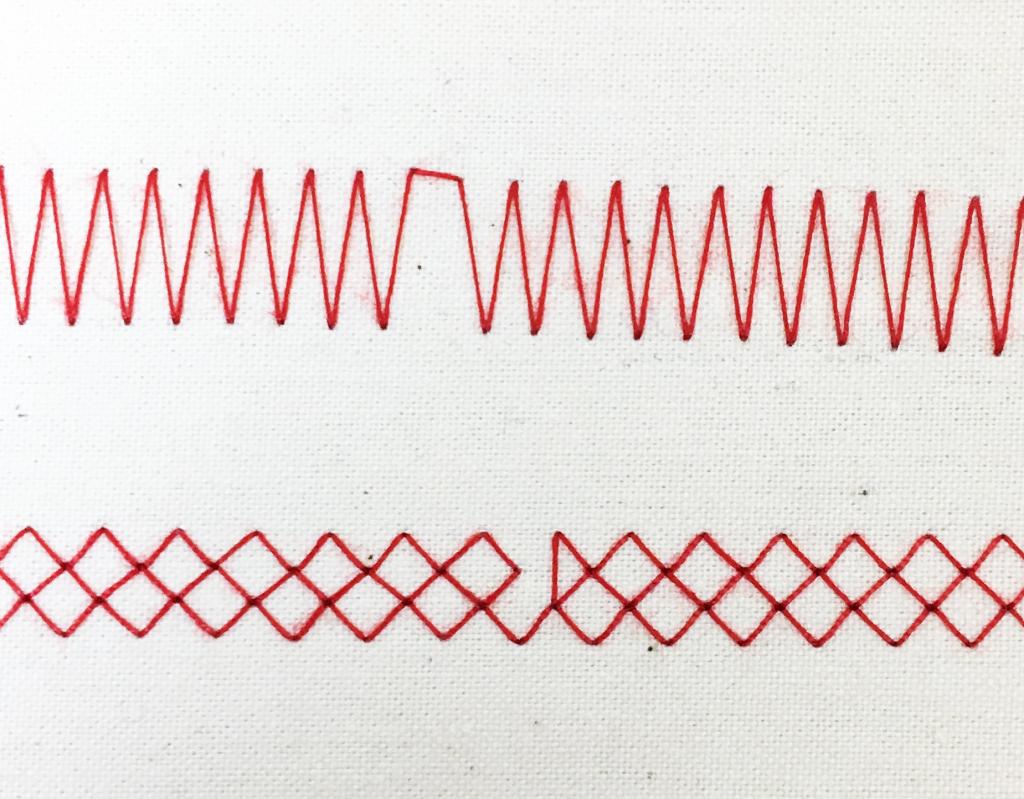

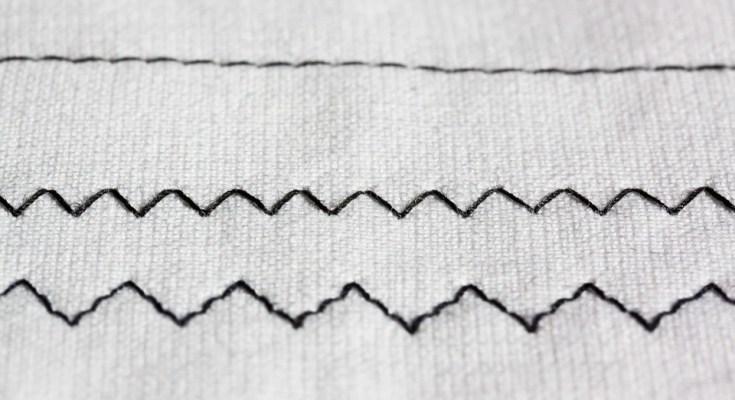

You were having the time of your life when you first spotted the missing sutures. With so many sewing tasks planned, you were pleased. When this one comes up, the whole thing unravels, since sewing a firm seam is the cornerstone of your sewing. The seam is not secure if you skipped stitches. Stitches that aren’t evenly spaced along the seam catch on the bottom of the piece you’re sewing.

Bạn đang xem: Why Is My Sewing Machine Skipping Stitches? Complete Guide

Calling your repairman right away will only make you more stressed out, and you don’t need it. To avoid the long wait for service, there are a few “home treatments” that can be applied right away.

What Would Cause A Sewing Machine To Skip Stitches?

Your Sewing Machine Is Not Threaded Correctly

Even individuals who have been sewing for a long time have the tendency to mis-thread their machines. To begin, check to see if your machine is functioning properly and if your stitches are correct.

Your Thread Tension Is Too Tight

Thread and fabric sizes must be taken into consideration when determining the proper tension for your thread. Use the same thread in the bobbin as you did in the top. This could lead to unequal tension and skip stitches if you don’t do it.

Manufacturers of sewing machines advise against making significant adjustments to the bobbin thread tension. However, if your thread breaks when sewing, you will need to adjust the tension of your thread. If you don’t have adequate tension, you run the risk of pulling your thread and snapping it or even cutting off a stitch. Make your tension dial turn counterclockwise in order to reduce the amount of pressure. Adjusting your tension is impossible if you are unable to do it. Your bobbin tension can be reset by a sewing machine repair professional.

Your Thread Is Poor Quality

There are many weights of thread to choose from. If you pull too hard on some threads, they can snap. In the eyes of the needle or the tension discs, another thread is so dense that it could break. This could be the cause of stitch breaks if you’re using shoddy thread. You should exercise caution while choosing a fabric for a project. Don’t buy bulk bobbin thread, as it’s often of poor quality. Suitable for hand stitching and small tasks, this thread may not be strong enough for machine sewing.

Your Needle Is Damaged, Bent, or Dull

Sewing machine needles can break or bend over time, especially if you deal with thick fabrics. Missed stitches can occur if the needle bends excessively. Reduce the stitching speed or use a sharper needle to avoid bent needles and skipped stitches.

Natural flaws or burs that emerge during the manufacturing process can also be seen in sewing machine needles. Before entering it into the machine, you’re likely to find a needle that is out of balance or damaged. It doesn’t happen very often, but it does. It’s always a good idea to pack a few spare sewing machine needles.

Your Bobbin Is Not Inserted Correctly

If you put your bobbin in backwards, you can still get stitches, but they won’t look as nice. Make sure to check the bobbin if you spot any missing stitches, especially after you’ve seen some good ones. Depending on the machine, the thread may need to be threaded into the bobbin case in either a clockwise or counterclockwise direction. Your sewing machine’s instruction booklet will tell you which way to turn the machine to operate it.

You Bobbin Case Is Full of Lint

While stitching, lint can accumulate in your bobbin case. It could impede your needle’s movement and prevent the hook in the bobbin case from making the correct stitches. Your sewing machine should be cleaned on a regular basis to avoid missing stitches.

Your Hook Timing Is Off

Your machine’s hook system creates the stitch loops when your needle is lowered. Your hook time is off if this doesn’t happen. Missed stitches may be an indication. Using a needle, slowly slide it through your plate, and watch for the time when it starts to rise again. Your loop should begin to appear at this point.

To address the problem, you may either try to fix it yourself or bring your sewing machine to a repair professional who can reset the time of the hook. Every time you bring your sewing machine in for routine maintenance, this issue is examined. To avoid any issues with your machine’s speed, always turn your handwheel to the right.

Your Fabric Is Too Thick

One or two sheets of fabric can be fed into a sewing machine at a time. As a result, if your fabric is too thin or too thick, you may wind up with sewn that have been skipped. Due of the needle’s inability to get through completely, this occurs. You should slow down your sewing pace and use a longer thread length if you are unable to cut through so many layers. Adjusting the pressure on your presser foot is also an option.

How to Fix Skipping Stitches on Your Sewing Machine

Replace a Bad Needle

The needle on the sewing machine is the most common reason of the machine not stitching. Even if the needle appears to be straight, it could be twisted. It could have a scratch or a dull point as a result of regular use. In addition to being easy to change, the needle is also the cheapest part of your machine. Replace the needle on your sewing machine and make sure you’re using the correct needle for the cloth you’re stitching to avoid skipping stitches.

Use the Correct Needle

A cook can identify the difference between ingredients and cookware by simply looking at them. As far as sewing equipment is concerned, it’s the same. It’s possible to get messed up needle stitches when you use the wrong needle for your sewing machine. For knitting knit textiles, a stretch or ballpoint needle is recommended, whereas an all-purpose needle is best suited for weaving. It’s also possible that a combination of a special needle and the cloth you’re sewing might be necessary. A leather sewing machine needle may be necessary if you’re working with leather. Learn everything you can about sewing machine needles in order to avoid frustration.

Use Better Thread

Xem thêm : How To Smock Fabric On A Sewing Machine? Step-by-Step Tutorial

Consideration must continually be given to the thread’s fineness. Many individuals believe that thread quality doesn’t matter, but a closer look at the different sorts of thread can change their minds.

This does not mean that the machine won’t be able to use a specific thread with stitch skips, but it may cause some inconvenience.

Adjust the Sewing Machine Tension

In order to fix a problem with uneven stitching on the sides and top of your fabric, you’ll need to change the sewing machine’s tension. Your sewing machine’s instruction manual is the ideal place to learn how to adjust the machine’s tension. If you lose track of your sewing machine’s manual, you may usually find it online. A sewing machine’s handbook is an invaluable resource for troubleshooting and getting the most out of your machine’s capabilities.

What Should Sewing Machine Tension Be?

The sewing machine’s pre-set tension is adequate if the top and bottom threads are the same. But if the threads differ in weight or fiber, you will have to alter the tension. To make the mechanics of two threads equal, the tension must be increased or decreased.

How do you alter the tension of the sewing machine?

- Find out how to adjust your sewing machine’s tension by reading the handbook.

- Tighten the loose tension by turning toward the number that is growing.

- Using a scrap piece of material, experiment with different tensions until you find the right one.

- The bobbin thread must be on the right side of the fabric, and the stitches must be uniformly spaced.

- Your stitches should be properly dispersed and the thread of your needle should not be on opposite sides of your fabric if you need to lessen your tension.

- Set the bobbin tension to the desired level. Then try changing the tension at the top of the chain.

Why Does My Sewing Have Looping Underneath?

You should adjust the top tension if you observe a loop on the reverse side of the cloth, because it is too loose in comparison to the bobbin tension. In the end, the bobbin thread pulls on the top thread far too much. The loop in the lower half of the fabric can be held in place by increasing the tension on the top thread.

As a result, stitches may be missed when the hook is lubricated incorrectly. In order to ensure that all of the hooking is done smoothly, an oil drop can be placed on the interior of the drop-in bobbin case (for a drop-in case) over the race (for an encasement that rotates).

FAQs

Is your sewing machine needle appropriate?

Check to see if the needle’s eye has been obstructed. Sizing and other chemicals in textiles can obstruct vision and result in defects such as skip stitches.

The absence of stitches should be noted. Make sure the needle is inserted all the way and in the precise place. You can remove the needle from your sewing machine if everything is well, and then replace it with a new needle. One should be cautious when handling a needle because of the potential for injury from a sharp tip. Skipped stitches are frequently caused by this.

A little bend, in addition to being sharp, might cause skips in the stitching process. Pulling on the cloth when stitching might cause the bend, which should be avoided at all costs. this.

Each new project is started with a brand new needle by professionals and experts. At a minimum, you should change the needle every 10 hours. Make certain it’s sharp enough, at the very least.

There are a lot of people who recommend Titanium Nitride-coated needles since they are superior to the rest and don’t skip stitches or break threads. They’ll endure a long time if you take care of them.

It’s important to use a needle that is both sharp and compatible with the fabric you’re sewing with. If replacing the needle doesn’t work, try a another size or kind of needle to see if it helps.

Choose a needle with a larger scarf when your machine isn’t timed perfectly to make the best stitches (Indentation on the back of the needle, in the vicinity of an eye). Because the bobbin hook swiftly loops the top thread, no skip stitches are created.

We use universal needles in sizes 75/11 or even 80/12 for most of our sewing projects. All knit and woven textiles can be sewn with this machine. You’ll need a larger needle, such as 16, or 18, for thicker fabrics. It is best to use a needle that is a bit thinner, such as an 8 or 9 or 10

A weak seam and irritating skipped stitches are the norm when trying to stitch flexible materials like knits or those composed of spandex fibers or synthetic suede with conventional needles. Stretch or Ballpoint needles can be used. To prevent skipped stitches, these needles include a specially shaped eye and deeper scarf.

Is the thread going through the thread path of the sewing machine perfectly?

Restarting the machine fixes the majority of stitching problems. It’s simple. Threading the machine again is important after removing the thread on top. The majority of the time, the skip stitches are the result of a place you failed to detect.

Are the fabric layers too thick for your sewing machine to handle?

Skip stitches are common when sewing through multiple layers of thick cloth or while sewing cross seams. In order to get to the bobbin’s thread, the needle must go through further layers. This happens when the needle becomes snagged in the looping operation. An unsteady stitch is a bad thing.

You can make the stitch a little longer than usual by adjusting the stitch length setting on your machine. Despite these improvements, you’ll still be unable to sew with thick fabrics without running across skipped stitches. So, check out this guide on how to create large layers of stitching on an embroidery machine.

Is the fabric too thin?

Xem thêm : What Is A Blackout Curtain? How To Attach Blackout Lining To Curtains Without Sewing?

Stitching will not be completed correctly when the needle is placed into the cloth and then rises, as the fabric’s thin layer lifts up as the needle moves. This results in missing stitches. In order to ensure that the fabric forms a horizontal line on the needle plate and that stitches are formed correctly, there is a way to assist in stabilizing the cloth.

Is the thread you are using the appropriate one?

It is possible to use nylon or polyester threads because they are elastic enough. Switch to this thread instead of the cotton one if you find yourself having to stop sewing because of missing stitches. Sewing elastic textiles is particularly well suited to polyester threads.

The most effective threads to use are those spun with cores.

Is the pressure and tension optimal for the fabric ?

The sewing machine’s tension is determined by the distance between the discs through which the threads flow. The tension can be adjusted using a dial on each machine. Dials can be shifted to increase or decrease a player’s level of tenseness.

Because we are social animals, a lower level of tension is better for us. Even with the lowest thread tension, the sewing machine should be able to stitch. There is a risk that the thread will break if you raise the strain. However, if you want to skip stitches, you may need to raise the tension.

Make sure the tension is correct.

Before you begin sewing, it’s a good idea to check the tension with a scrap of the same fabric you’ll be using for the project. Check the top of the material to see whether it is slack to determine if the tension is low (back of seam). If this is the case, gradually ramp up the strain. Repeat this procedure until the fabric is at the correct tension.

Always make use of the controlled acceleration provided by a motor. Stay away from it and take off like a jet. Breaking stitches should not deter you from taking a rest.

The correct presser foot and feeding, needle plate, and other equipment are required.

The problem can be solved by adjusting the pressure. Excessive pressure is the most common cause of skipped sutures. If you observe skip stitches while sewing delicate cloth, reduce the pressure you’re using to sew. It will take a little more pressure when working with thicker fabrics.

Do you know how to control pressure? If your sewing machine has a screw setting pressure knob, you’ll want to experiment with it. Located on the top of the sewing machine above the needle and presser foot, or to the left.

Hook lubrication might cause stitches to be missed in some situations. In order to get the best results, you can put an oil drop on the bobbin case (for a drop-in case) or the race (for a bobbin case that rotates) to help this area function efficiently and guarantee that hooking occurs smoothly, which results in perfect stitches.

Did none of this work?

You can experiment by stitching on a wide range of materials. It’s possible that your machine isn’t designed for the type of sewing you’re doing if it only has problems with a specific type of fabric or operation.

The hand thread and needle can be used to stitch over the stitches that have been skipped.

If the problem with skip stitches persists despite your attempts, it may be due to a problem with your equipment. It’s possible that the timing on your system is out of sync, resulting in an inadequate number of loops. Skipped stitches may be evident if your machine’s needle-to-hook timing is off. The hook or looper’s point could be damaged in the worst-case scenario. Maybe you’ll need to get a new one altogether.

If you don’t know how to fix this machine, you’ll have to hand it over to a trained expert who can do it.

Conclusion

It’s all done and dusted! My sewing machine may not be able to stitch because of a problem with the machine’s settings or tension. As a result, it’s critical that you check your sewing machine thoroughly before getting started.

We sincerely hope you found this to be an educational experience. In the event that you don’t already know how to clean your sewing machine, here’s a great instruction. Your machine will not malfunction if it is regularly serviced.

Nguồn: https://spasifikmag.com

Danh mục: Sewing Tips