Pressed board cabinets can be repaired in more ways than just drying and restoring the pressed board itself. Mold removal from your furniture is also a part of the process.

- How To Fix Water Damaged Plaster Ceiling? Easy Step-by-step Guide

- How To Remove Water Damaged Ceiling Insulation? Comprehensive Guide

- How To Repair Water Damaged Soft Floating Floor? Step-By-Step Guide

- How To Replace Water Damaged Door Frame? Easy Step-by-step Guide

- How To Soften Water Damaged Leather? Complete Step-by-Step Guide

This is why we wrote about how to fix water-damaged pressed wood boards and remove mold from the said boards in the first place. We also discussed how water damage occurs to pressed wood. Repair expenses and insurance coverage for water damage were also considered.

Bạn đang xem: How To Repair Water Damaged Pressed Board Cabinets? Comprehensive Guide

How Do Pressed Wood Acquire Water Damage?

Partially engineered wood products like pressboards and particleboards can be used interchangeably with pressed wood. They are, nevertheless, distinct from one another.

Pressboards are created from recycled paper, whilst pressed wood is constructed from wood scraps. Both are engineered to be long-lasting and environmentally friendly.

What sets them apart from particle boards is their manufacturing technique. The extrusion method is used to make particleboards. Using a pressing procedure, the two are created

No matter how they were built, all of them are susceptible to water damage when exposed to excessive moisture and water. They swell and expand as a result of absorbing an excessive amount of water.

The pressed wood’s fibers are damaged by water, making repairs difficult. However, we’ve included advice on how to correct them in the next section.

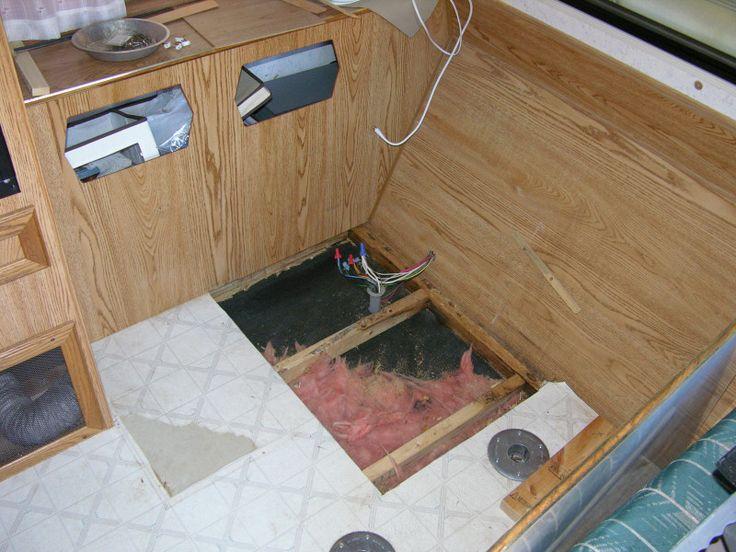

Steps In Repairing Water Damaged Pressed Wood Board

Step #1. Dry the board

The first step in dealing with any water-damaged piece of furniture is drying it out. It takes a long time for pressed wood boards to dry naturally, but this is the only option. To speed up the drying process, open the windows.

Step #2. Smoothen the boards

Sanding is important because water-damaged pressed wood swells when it’s water-damaged. Using sandpaper, sand down the wood’s raised portions.

Fine-grit sandpaper can be used to finish the pressed wood. Use medium-grit sandpaper when eliminating the edema.

Step #3. Remove damaged areas

Examine the condition of your pressed wood once you’ve finished sanding the boards. Remove the powdery bits of the wood by poking it with a knife and cutting out the damaged areas. Finally, use a vacuum to remove any residual powder off the board.

Step #4. Fill the holes

Wood filler should be applied after sanding and removing the damaged pieces. After you’ve applied the wood filler, smooth it out and remove any excess with a scraper. Wood filler is available in a variety of forms.

Step #5. Finish the pressed wood repair

You can use fine-grit sandpaper again to smooth out the board after it has dried from the filler. Your sealant will stick to the board better if you do this. The wood should be protected from swelling by applying a waterproof sealant.

How to remove mold from water-damaged pressed wood cabinets

Mold and mildew are other issues that might arise as a result of water damage. Why did we offer instructions on removing mold from pressed wood cabinetry? In order to get rid of mold from your cabinets, follow these steps:

Step #1. Protect yourself

To avoid respiratory issues caused by mold, wear a respirator when working in the area. Wear long-sleeved clothing, safety eyewear, and gloves. Keeping your skin away from mold spores is a major reason for this.

Step #2. Scrape off mold

Xem thêm : How To Clean Water Damaged Car? Comprehensive Guide

Scrape the mold off of your pressed wood board if it is visible. You can remove obvious mold with a soft bristle brush or a moist cloth.

Step #3. Make a bleach and water mixture

Add one gallon of water to a bucket and one cup of bleach. A sponge is then used to cleanse the pressed wood boards with the bleach-water solution. To avoid discoloration, do not saturate the board with the mixture.

Step #4. Dry and finish

Allow the pressed wood to completely cure before attempting any more projects with the material. You may speed up the drying process this time around by using fans. After that, apply a stain-blocking primer to the wood to prevent mold from forming in the near future.

To prevent swelling of the pressed wood board, prime with a solvent-based primer rather than a water-based primer. After two coats of primer, you can add further coats to the board to ensure that the edges are well covered. Finally, wait for the priming to dry before painting over it.

Costs of repairing pressed wood board cabinets

Repairing cabinets typically costs between $281 and $429. This covers the removal of the cabinets, preparation of the work space, and cleanup. Finishing materials, for example, are included in the package.

The average range includes the allowance for equipment. For this reason, it may be more expensive to repair water damage on pressed wood cabinets.

Additionally, this price does not include the cost of repairing the leak in your ceiling or wall that caused the water damage in the first place. If you’re unsure of your repair budget, talk to your insurance carrier and attorney about water damage coverage.

6 Particle Board Care Tips

Keep Moisture Away

Moisture is extremely damaging to particleboard. As a result, it is nearly never employed in outdoor settings. Always avoid getting damp particleboard (such as in the form of flooring, cabinets, or furniture). When cleaning it, use as little water as possible. Make sure you only apply a very small amount of water or other cleaning agent, and then promptly wipe it away with a dry cloth. Work in small sections that can be dried quickly so that the material doesn’t have a chance to absorb water.

Ensure Proper Sealing

There must be a moisture-proof sealer applied to all of the particleboard’s perimeters and corners. Swelling or warping will occur if even a little portion of the surface is exposed to the elements. Particleboard can get discolored as a result of water absorption. Ensure all of the particle board’s surfaces have been thoroughly sealed before purchasing it. If the sealer fades off over time, you will need to reapply it.

Never Wear Outdoor Footwear on Particle Board Flooring

Unlike hardwood and other wood flooring, particleboard does not hold up as well. Damage to floors can be done permanently if they are subjected to significant foot traffic in high heels or heavy outdoor footwear. Placing padding under heavy furniture will help protect the floor from damage from heavy items. Particleboard flooring should never be subjected to large weights.

Ensure Adequate Support for Particle Board Cabinets

In today’s kitchens and bathrooms, particleboard cabinetry is a common choice. When storing heavier objects in your cabinets, you may want to select for more robust materials.” The cabinets must be supported properly if they are made of particleboard. Without proper support and care, they could buckle under the weight of their own weight.

Move Particle Board Furniture with Care

If the veneer is real wood, particleboard furniture can seem very nice. The inside, on the other hand, is not as durable. If you plan to transfer a large piece of particleboard furniture, dismantling it and transporting it piece by piece will help limit the risk of damage.

Use Nails and Fasteners Specifically Manufactured for Particle Board

Particleboard is incompatible with nails and screws because the wood particles will progressively dissolve and fall apart if they are used. Particleboard fasteners and screws should not be replaced until absolutely necessary. If necessary, only use fasteners designed for this project.

Compare Particle Board vs Plywood Cabinets Costs

Particle Board Cabinets

It’s prohibitively expensive to build cabinets out of solid hardwood. As a result, the cabinet box — the section hidden behind closed doors and drawers – is constructed from less expensive materials.

How Much Do Particle Board Cabinets Cost?

Particle board is less expensive than plywood since it is created from waste materials. For mid-grade cabinets, a 10% to 20% price reduction is typical (most high-end cabinets use plywood, not particle board).

Xem thêm : How To Refinish Water Damaged Window Sash? Special Tips and Tricks

Between $5,000 and $15,000 is the average cost of kitchen cabinetry for a typical home. For example, a particle board set costs $7,000; a plywood set costs between $7,700 and $8,400. It’s important to keep in mind, however, that these are only broad guidelines as to pricing.

Particle Board Cabinets Pros

Particle board is less expensive in part because of its well-earned reputation. Plywood, on the other hand, is actually a more dense material. Particle board made of high-quality materials is durable and stable.

Precision machining of particle board produces a surface with a smooth, seamless appearance. With this level of precision, it’s easy to install without any mistakes.

Particle Board Cabinets Cons

High-quality particle board can’t compete with plywood for strength. Heavy countertops placed on top of particle board cabinets may require additional support. Particle board is more vulnerable to damage from scratches and dents.

Particle board is more prone to water damage than plywood because of its lower water resistance. Both are, of course, not watertight. In the event of a significant leak or flooding, both particle board and plywood can be destroyed.

Plywood Cabinets

Cabinet boxes are more commonly made from plywood than particle board, and this material has traditionally been favored for its sturdiness. The material, like particle board, has both advantages and disadvantages.

There are many layers of veneer in plywood. For increased sturdiness, the layers are constructed with the grain running in alternating directions. Various thicknesses of plywood are available. Some of the more expensive cabinets will use 3/4-inch plywood, while others use 1/2-inch plywood.

How Much Do Plywood Cabinets Cost?

Between 10% and 20%, plywood is more expensive than particle board. If you use plywood instead of particle board, a set of cabinets that would have cost $10,000 will cost $11,000 to $12,000. 3/4-inch plywood is more expensive than 1/2-inch plywood, which isn’t a surprise. A single sheet can cost as much as an extra $10, although that’s not uncommon.

A mix of particle board and plywood is offered by some cabinet manufacturers. You can use plywood for the sink foundation, but particle board for the rest of the cabinet. As a result, the price disparity is minimized.

Plywood Cabinets Pros

The interweaving nature of the plywood boards makes it a stronger material that can hold more weight. Moisture, scratching, and denting are no match for it.

Although some people aren’t worried about how their cabinets look on the inside, others like the aesthetic of plywood over particle board. Also, the color of particle board is superior.

Plywood is more easily fixed and repaired than other types of wood. In addition, it is more resistant to drilling.

Plywood Cabinets Cons

Variability – Plywood isn’t as consistent as a solid piece of wood. Where the boards were joined, there may be gaps or holes. Because the cabinets won’t line up exactly, installation may be more challenging as a result.

Cost – Plywood is more expensive than other materials.

Conclusion

After learning how to repair water damaged pressed board cabinets and remove mold from wood, we hope that you will be able to prevent water damage from occurring to your cabinets in the future. If you ever find yourself in a similar scenario, you may always refer to this post.

Nguồn: https://spasifikmag.com

Danh mục: Damaged