If you have particle board in your home, you should know how to fix water damage. Particle boards have gained popularity since they can be used anywhere that traditional wood can, including in the kitchen, bathroom, and even as a means of storage.

- How To Fix Small Water Damaged Hole Drywall Ceiling? A Step-by Step Learning Guide

- How To Protect Cabinet Doors In Water Damaged Kitchen? Ultimate Guide

- How To Replace Section Of Water Damaged Wall? Comprehensive Guide

- How To Repair Water Damaged Wallboard? Step-By-Step Guide

- How To Sell Water Damaged House? Comprehensive Guide

Particle boards are resilient, however they can be damaged by water such as steam, floods, and water dripping off dishes in the kitchen. Mold can grow in these areas if maintenance is delayed.

Bạn đang xem: How To Repair Water Damaged Pressboard? Step-By-Step Guide

However, ruined particle boards caused by moisture are no longer a concern. Keep reading this post as we provide answers to your questions about particle board.

What is plywood and how is it made?

Plywood is an engineered timber product that is created by adhering thin sheets of wood veneer together in layers (or plies) using pressure and heat to create a thicker, stronger, and more flexible flat sheet.

The logs used to construct each sheet are steamed or dipped in hot water to soften them, and are then fed through a lathe to be peeled into thin plies, typically between 1mm and 4mm thick, which are used to make up the layers of each sheet.

Its low price and vast range of practical applications make it a go-to material for construction.

High-quality plywood is sturdy and won’t warp or split when exposed to humidity fluctuations, making it useful in many settings.

How this versatile timber material can be used for various applications

Softwood and hardwood plywood are both often used in manufacturing, and both types of plywood can be found with varying degrees of finish.

Here are some of the many applications for plywood and the reasons it makes a great material:

1. Exterior Wall Sheathing

Frames of either 24 or 26 feet are typically clad on the exterior with plywood sheathing, a standard method of construction for new homes in the United States and Canada.

Plywood panels are connected to each stud to increase the frame’s strength and stop it from sliding horizontally or vertically.

Because of its adaptability, the building formed by this method functions effectively in extreme weather and during earthquakes.

2. Interior Walls

Plywood of a certain grade is ideal for use in installing wood paneling or framing interior stud walls.

It’s true that most plywood won’t be seen once the project is finished, but some highly finished A-graded plywoods are excellent for facing inwards and can be painted or stained to offer a lovely natural wood finish.

3. Roofing and Flooring

Many interior flooring projects employ plywood as a subfloor or for sheathing roofs.

Plywood panels with tongue-and-groove edges can be slotted together to form a sturdy floor, and they can also be used as a waterproof membrane or tile base for roofs.

Plywood performs admirably in both contexts.

4. Other Construction

Eaves and soffits are often made entirely of ply or have a plywood skin.

Xem thêm : How To Fix Water Damaged Swollen Wood Table? Step-By-Step Guide

Certain types of plywood are manufactured for the express purpose of being used as a siding product, and they are designed to mimic the look of reverse board and batten.

Plywood is frequently used by contractors in the building industry for temporary floors and concrete forms during the construction of detached garages and sheds.

5. Furniture

Making furniture out of plywood can be both functional and economical.

One nice-looking side can be achieved by using high-quality plywood, while the rest of the structure can get away with a lower grade finish.

Plywood may be used for practically any type of furniture you can think of, therefore it is frequently found in custom-made pieces like dressers, closets, media centers, shelves, bookcases, console tables, and so on. The list is so long that it’s meaningless to count them all.

6. Cabinets

Cabinet carcasses (in kitchens, bedrooms, and elsewhere) are ideal projects for plywood.

Plywood of decent quality is more than adequate for use as cabinet backs and sides in the vast majority of cases, and it is vastly superior than more conventional materials like chipboard or MDF in terms of durability, longevity, and resistance to splitting.

7. General Projects

Skateboard ramps, rabbit hutches, and doghouses are just a few of the numerous different uses plywood has around the house.

Plywood is a favorite material of do-it-yourselfers because it can be used to create a wide variety of practical products.

Using plywood sheets, we’ve even published a number of our own simple DIY projects.

There are a ton of creative uses for plywood around the house; why not check them out?

It’s fantastic that it may be used either indoors or outdoors, wet or dry, and in a variety of thicknesses and grades.

It reliably and affordably creates a high-quality end result.

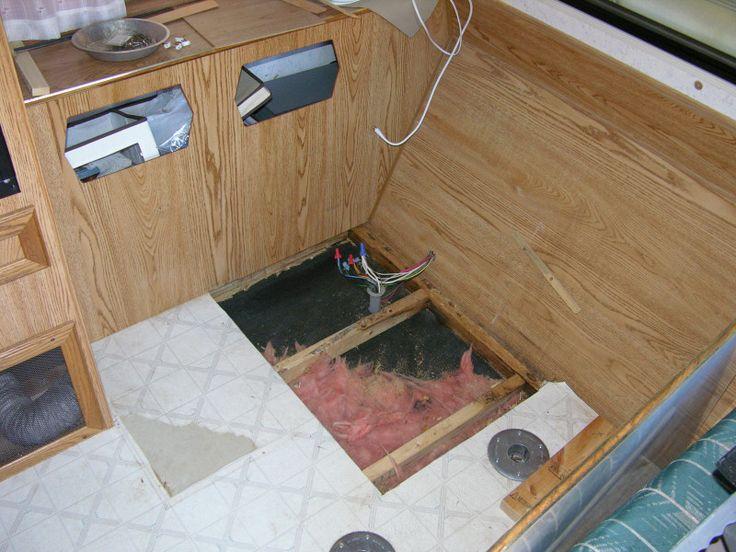

Repairing Your Water Damaged Particle Board

Knowing how to quickly repair particle boards is important because of their susceptibility to damage. Here are some instructions for fixing particle boards that have been exposed to water.

Step #1. Ensure that the particle board is clean and dry

First things first: inspect your particle board for mold. Molds can grow in particle boards if water damage is not properly addressed. This fungus has the potential to cause illness in humans.

Make a bleach and water solution and use it to kill any molds you find. Bleach solutions might leave a lingering odor, so crack open some windows to let in some fresh air. However, if there are a lot of molds, it’s best to use a knife to scrape them off.

The next step is to wait for the particle board to dry. This is typically a lengthy process, but hairdryers and towels can help you get through it more quickly.

Step #2. Level the surface of the particle board

Get some sandpaper with a medium grit, then use it to smooth up the particle board. Make sure the ground is perfectly flat.

Xem thêm : How Much To Repair Water Damaged Ceiling? A Helpful Guide

All particle board furniture can be constructed in the same way. In any case, if you are working on one, you can always apply new coats of paint to make it look fresh.

Step #3. Use a knife to remove water damaged areas

Water damaged sections of your particle board can be easily cut away with a sharp knife. Cleaning the board and getting rid of dust and powders is the next step after repairing the broken spots.

Step #4. Fill in the holes with wood fillers

It’s time to get the wood fillings ready. When using a scraper to fill in the holes left by removing the water damage, do it gently. Then, clean up the surface of any remaining wood filler.

Step #5. Sand it, and you are good to go!

Finally, pull out the fine-grit sandpaper and buff the particle board until it’s smooth. After you’ve done that, your issues with particle board will go.

How Can You Avoid Water Damages?

Avoiding water damage is one of the simplest methods to preserve the quality of your particle board. But how are we going to accomplish this? So, how about some strategies?

Method #1. Avoid moistures

Regular use of towels and mops can help you keep your home dry by removing moisture from the floor. Additionally, it is preferable if there is adequate ventilation. To aid in the evaporation process, you can either open the windows or utilize a dehumidifier.

Method #2. Use waterproof coating

While a waterproof coating won’t prevent water damage entirely, it will lessen the impact. The lifespan of your particle board will increase as a result.

Method #3. Laminate your particle board

Adding a laminate to your particle board might also assist reduce swelling. A new layer of laminate can be applied when the particle board is sanded down.

Method #4. Paint them

Alternatively, you may try painting your particle board. The first step is to prep your board by sanding it down. Six hours of drying time is recommended.

Apply the first coat of paint and wait for it to dry. You should sand it again to keep it smooth. To apply a second coat of paint, just follow the same steps.

How to Protect Plywood From Water Damage

Indoor or Outdoor Use

Determining whether your plywood will be used indoors or outside is the first step in preserving it from damage. Penetrating oil containing an anti-fungal preservative, for instance, may be all that’s needed to treat a subfloor at an entryway, where the risk of water and moisture damage is low. For an exterior siding application, however, the plywood will need to be coated with a protective waterproofing coating, either by painting it or spraying it on.

Types of Waterproofing

Many different waterproofing options exist for plywood. Waterproofing that may be painted or sprayed on is the most frequent variety seen at hardware stores. These are usually liquid latex compounds that are brushed onto the wet plywood. Upon drying, they’ll create a tough, plastic coating. In addition to the aforementioned options, penetrating oils and sealers, plastic sheets, and interlocking membrane systems are also at your disposal.

Application for Liquids

Whether you plan to utilize the plywood as a finishing material or a structural component will affect the application method you choose. Most liquid waterproofing chemicals and sealers can be painted on with a brush, rolled on with a roller, or sprayed on with an electric paint sprayer. While overlapping and interlocking membranes can be installed without the use of nails or staples, plastic sheeting often requires such fasteners. When plywood is used as a substrate for tile or natural stone, it is typically covered with a paint-on or interlocking membrane, while overlapping is the norm when used as a substrate for exterior siding. The natural wood grain pattern in finished plywood is typically preserved with spray-on sealers and preservatives.

Importance of Manufacturer Guidelines

It is critical to adhere to the guidelines provided by the plywood’s manufacturer when applying a protective coating once the installation is complete. To properly waterproof plywood before laying ceramic tile, for instance, you should consult the tile manufacturer’s guidelines. For the same reason, when it comes to safeguarding the plywood that is beneath your siding, you should always follow the guidelines provided by the manufacturer. Any products used during the installation should have their warranties protected by according to the manufacturer’s instructions for the final product.

How Can You Take Care Of Your Particle Board?

There are many situations in which particle boards would prove useful. We may install them on walls, in cabinets, on doors, and even in the flooring. They’re useful to us, therefore we need to look out for them.

Do’s

- It needs to be stored in a dry space.

- Repair broken parts right away.

- Particle board requires delicate handling.

Don’ts

- Don’t ever put particle board there.

- Don’t hammer on it or screw it down.

- Don’t adhere tiles directly to it when using it on walls or floors.

How About Moving Your Particle Board?

There are a plethora of particle board moving firms available to assist you with any and all of your needs today. As it is difficult to handle particle board furniture on your own, they can assist you in relocating it.

But before you hire one, make sure they are properly licensed and insured. Find out if the companies have any sort of insurance by asking them. Any breach of the insurance contract may necessitate the services of an attorney.

Conclusion

Restore your particle board any time after knowing how to repair water damaged particle board. Ensure to perform the steps correctly so that you can avoid further hazards from water damaged particle boards. Keep in mind that it is always better to be safe than to endure a damaged particle board.

Nguồn: https://spasifikmag.com

Danh mục: Damaged